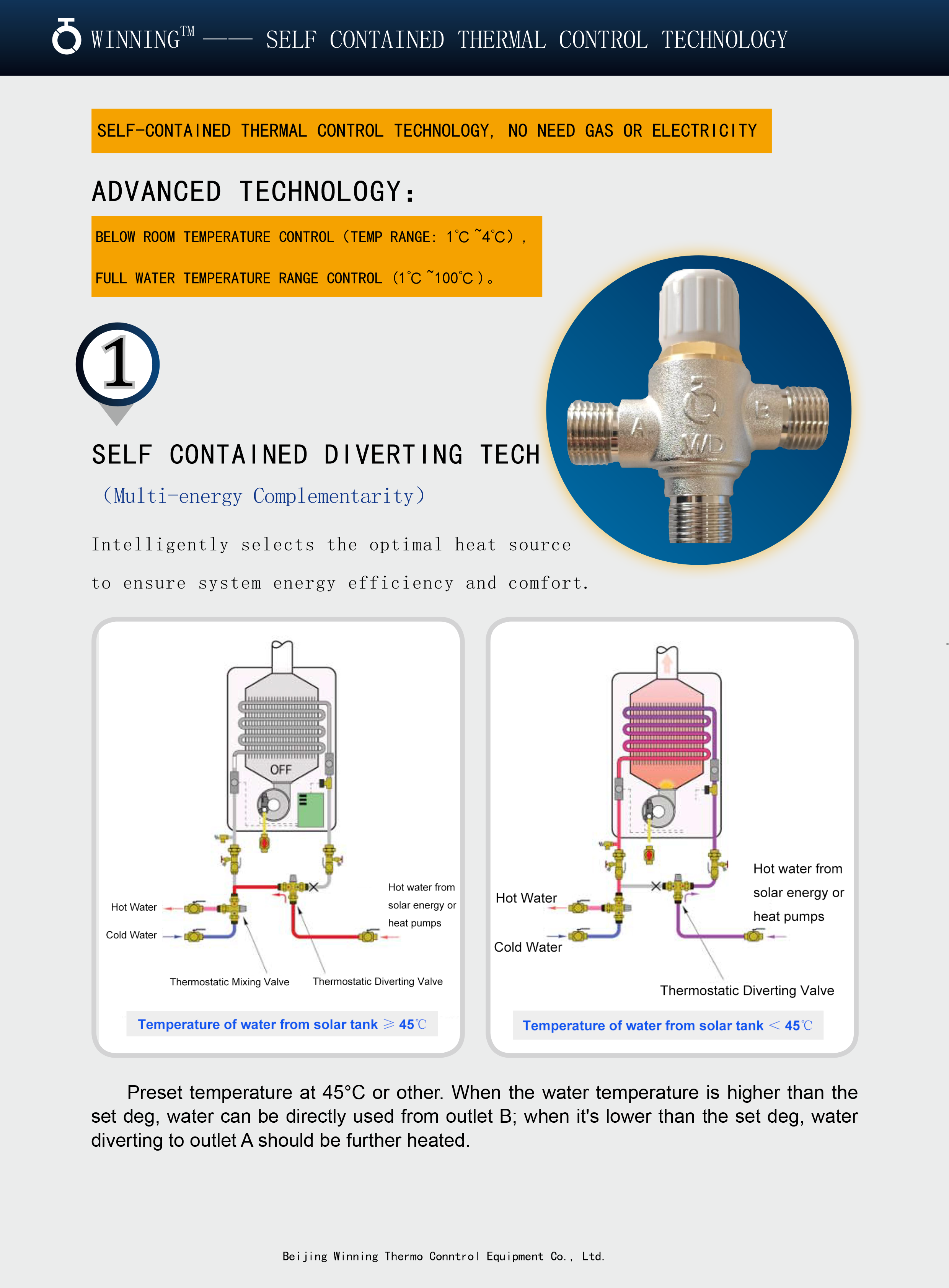

Residential Instant Water (Zero-Cold-Water) Upgrade Solution

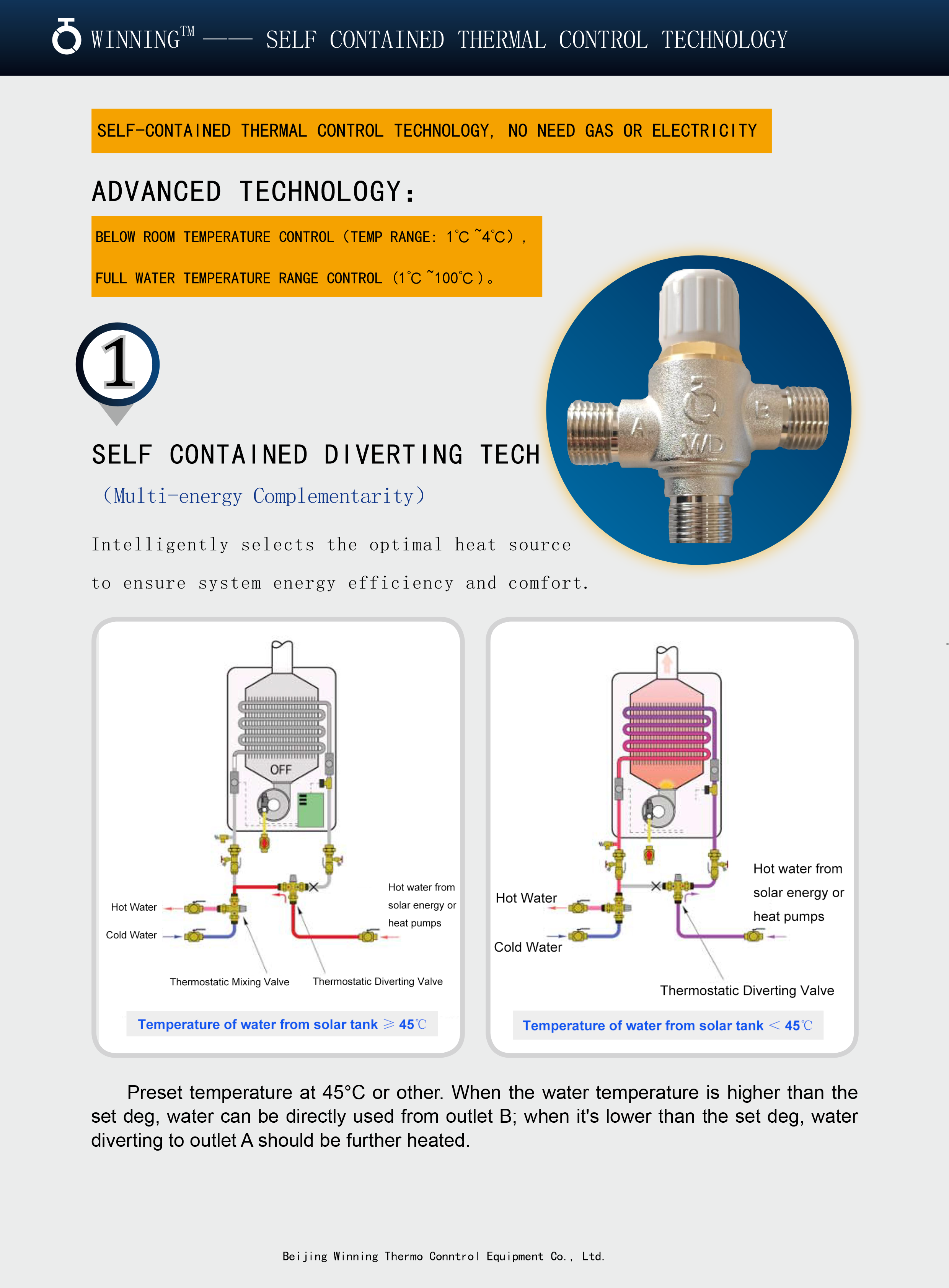

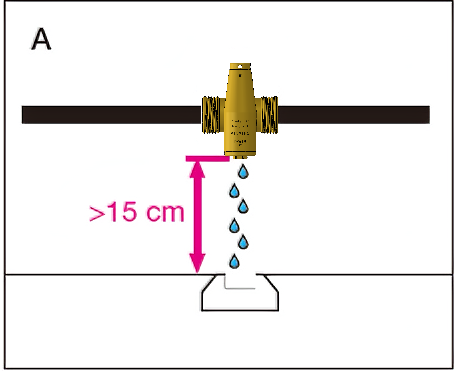

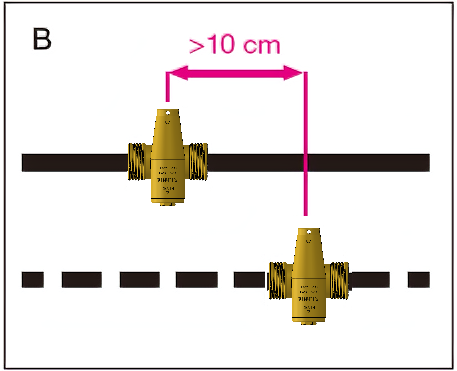

During installation, ensure that all dust and foreign particles are thoroughly removed from the unit and its connected piping. Install the directional control valve at the cold water inlet of the point-of-use electric water heater (commonly known as a "mini water heater" or "under-sink water heater"). When the hot water tap is opened, the mini water heater immediately supplies hot water, simultaneously flushing out and utilizing the cold water remaining in the hot water pipe.

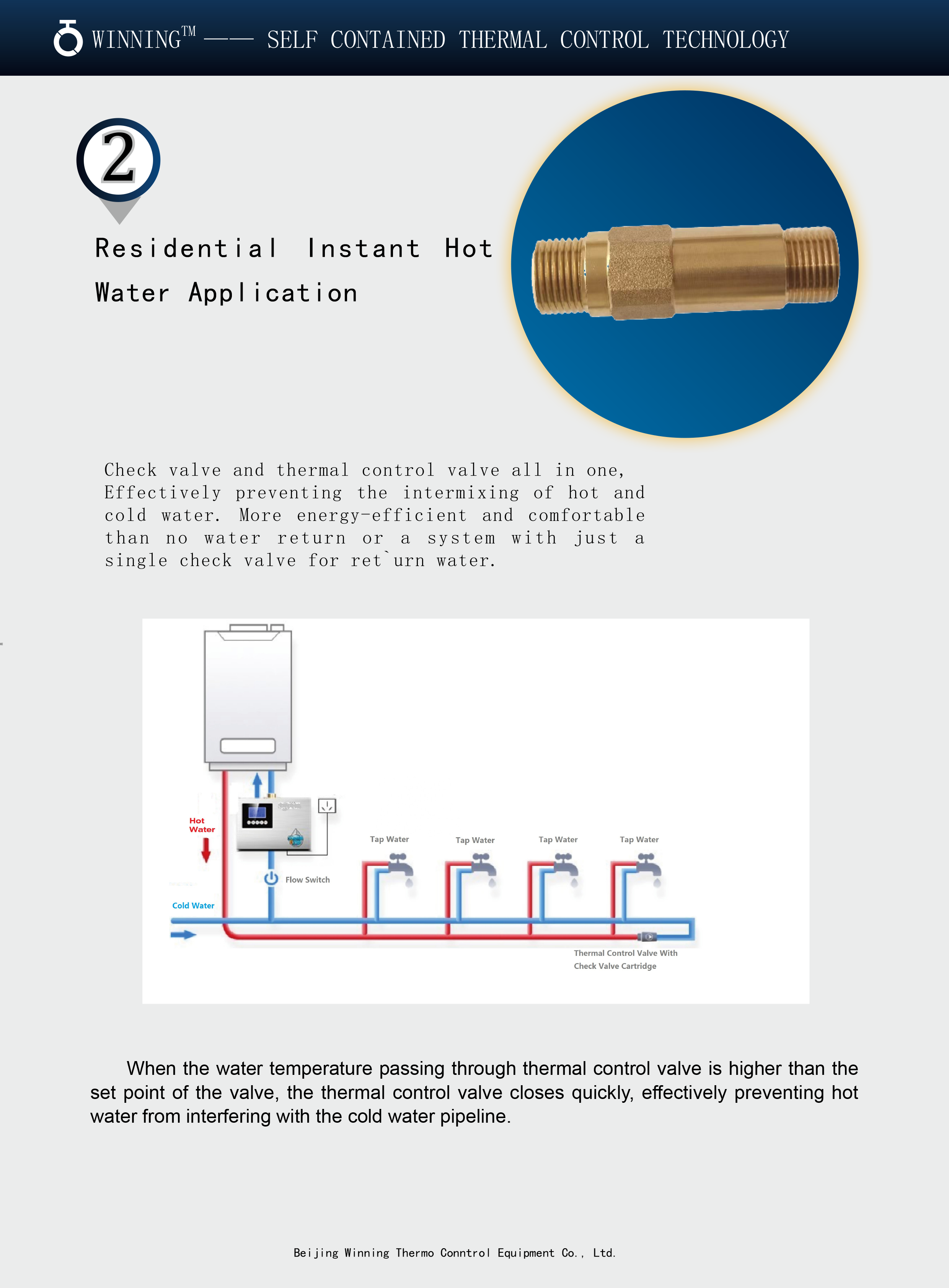

This instant water upgrade solution integrates the functions of a check valve and a thermostatic valve into a single component. It eliminates the need to wait for hot water circulation and removes the requirement for traditional instant water systems to install a dedicated recirculation pump, separate thermostatic valves, or check valves to isolate the hot and cold water lines. As a result, it significantly reduces both initial installation costs and complexity, while cutting overall system operating costs by more than 30%.

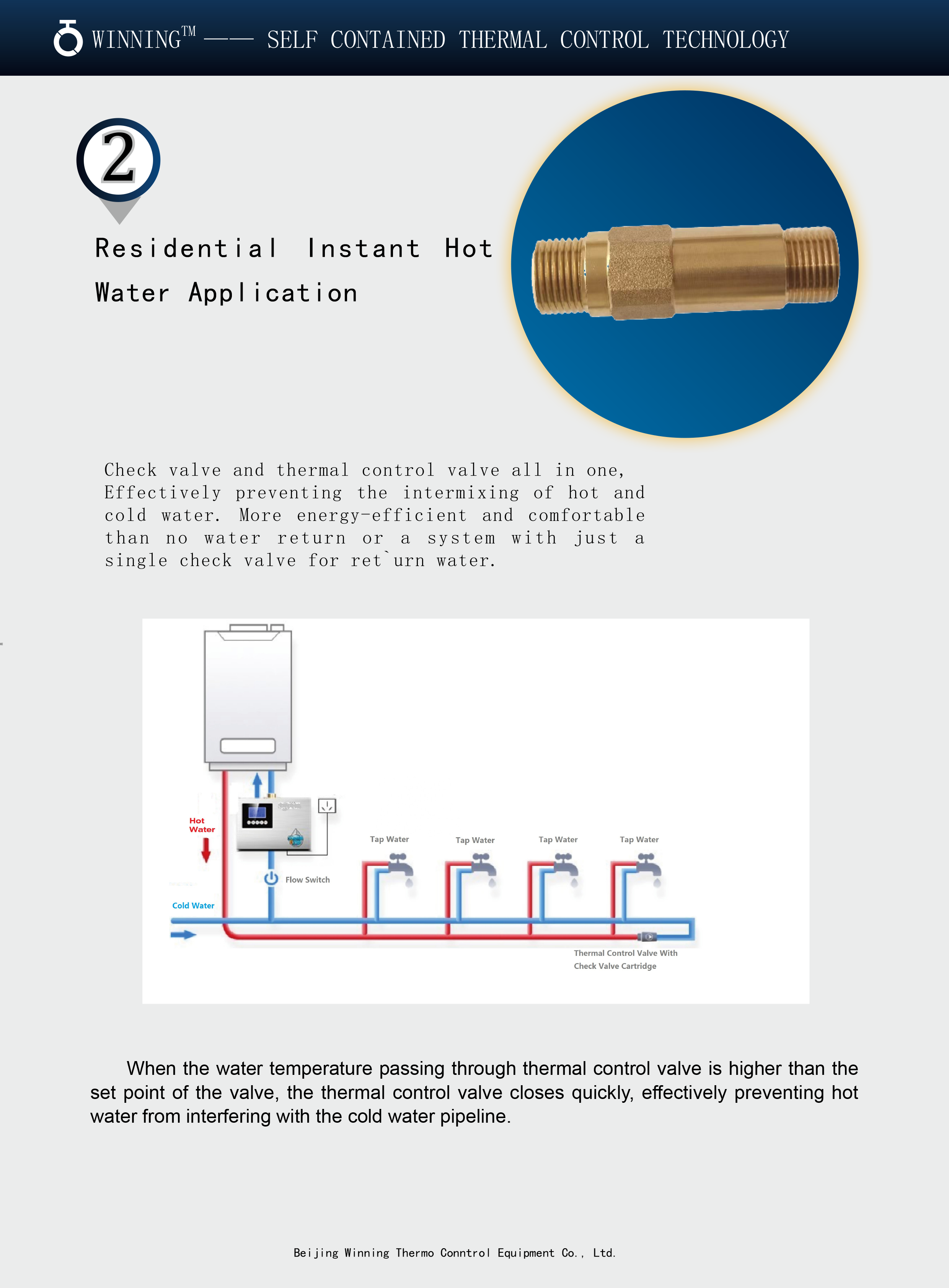

Residential Zero-Cold-Water Hot Water Applications

This system effectively prevents cross-mixing between hot and cold water lines, offering superior energy efficiency and user comfort compared to conventional return-water systems that rely solely on a check valve.

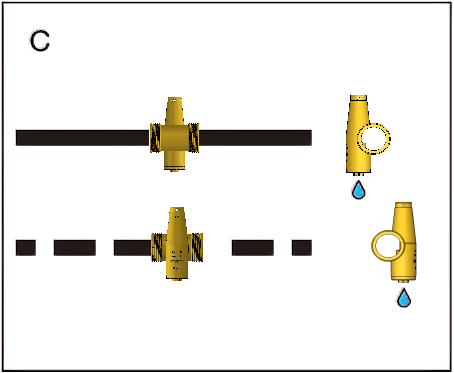

When the water temperature passing through the zero-cold-water thermostatic valve exceeds the preset threshold, the valve rapidly closes, thereby preventing hot water from migrating into the cold water piping. The thermostatic valve is factory-set to activate at 37°C (or another specified temperature) and can be customized to meet specific customer requirements.

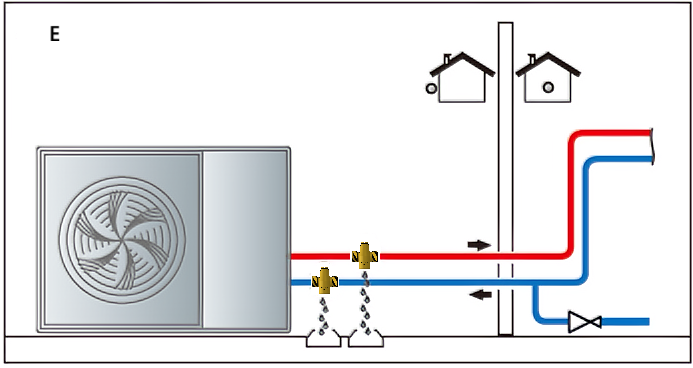

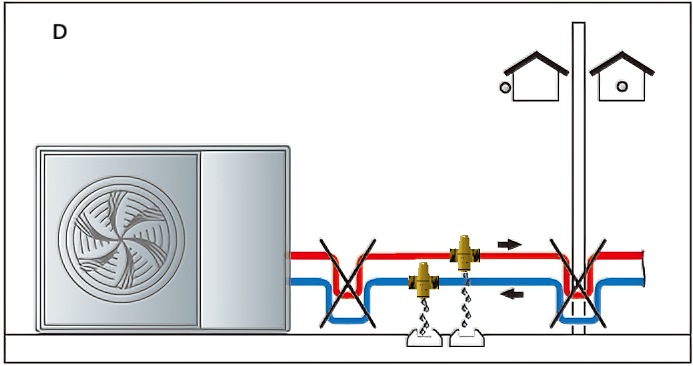

Commercial Zero-Cold-Water Hot Water Applications

This system reduces initial investment and operating costs while ensuring consistent, thermostatically controlled hot water delivery—providing truly instant hot water at the point of use.

When the water temperature in the system falls below the setpoint of the thermostatic valve, the valve automatically increases flow rate to rapidly raise the pipe temperature to the desired setpoint. Conversely, when the water temperature exceeds this setpoint, the valve automatically reduces the flow rate, allowing the temperature to quickly return to the target level. This dynamic regulation establishes a continuous balance between heat loss and thermal replenishment, achieving instant hot water availability while minimizing energy waste to the greatest extent possible.